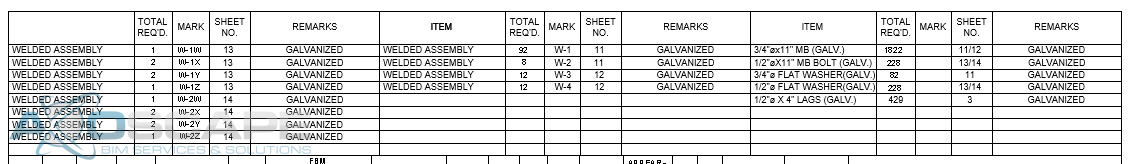

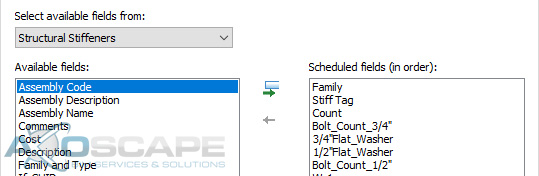

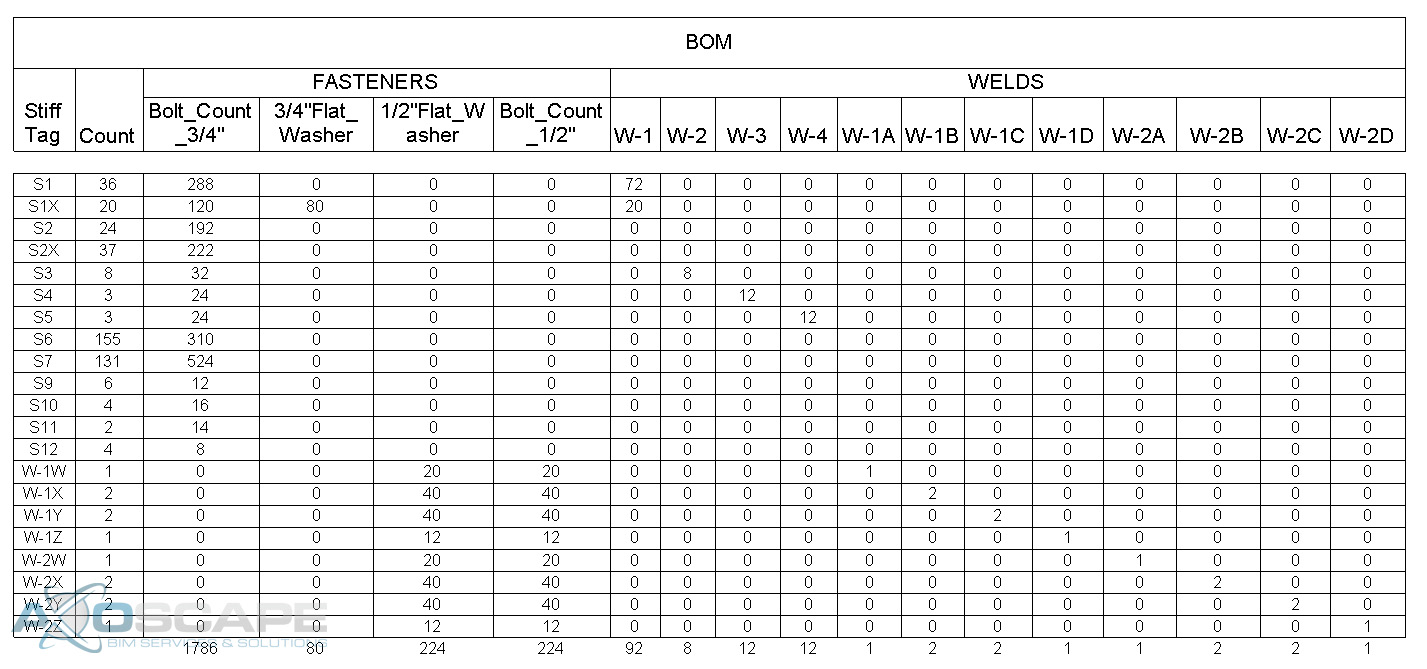

This workflow was created from a project for RM Rodgers, Inc., a subcontractor who specializes in wood beam systems with over 50 years of experience. This was one of the first projects where 3D modeling was required for coordination purposes. This article will cover how to schedule out beam connection components. Here’s a look at the schedule.

This schedule needs to reflect the everchanging conditions of the project and update dynamically. For example, if an existing connection is altered, the bolt counts and other parts change. In addition to the connection changes, the elevation sheets and B.O.M schedule must be updated.

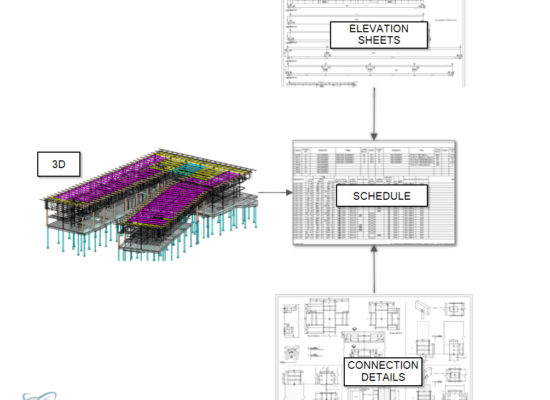

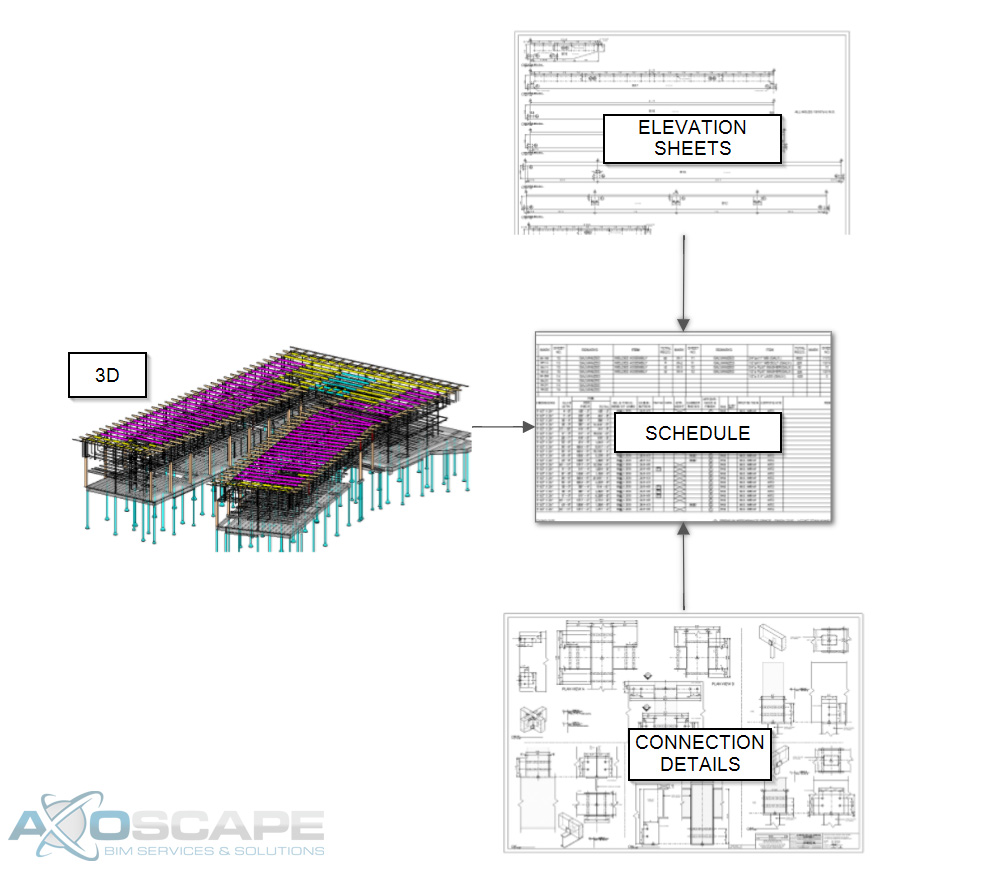

This is your typical workflow when it comes to producing cut sheets for any manufacturer.

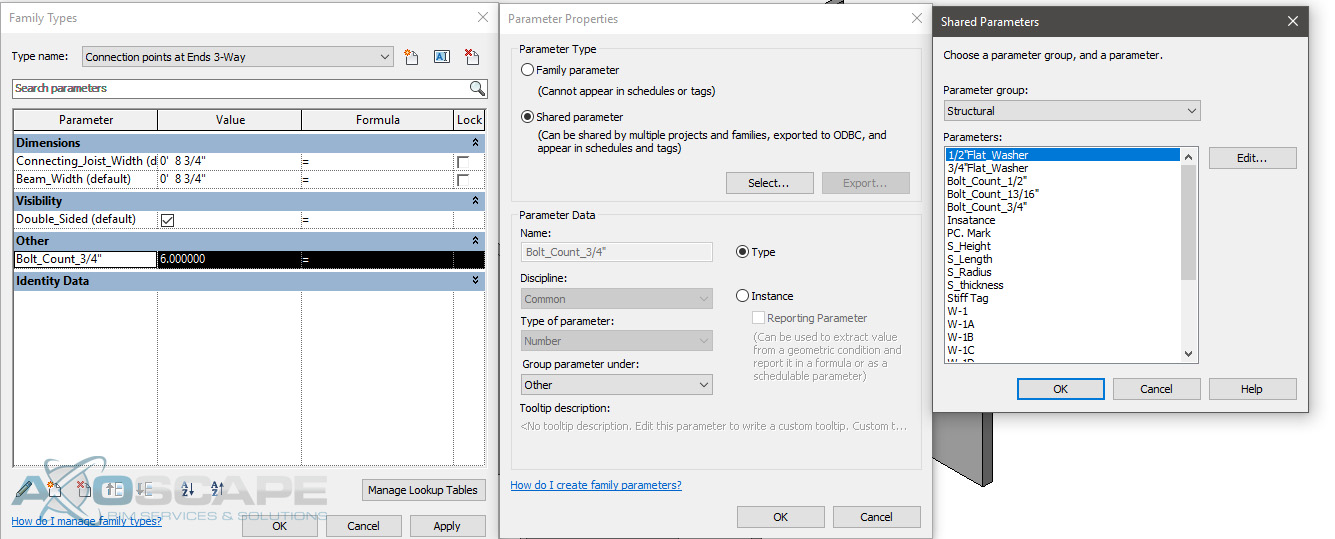

Manually updating every sheet in the project is tedious and time-consuming. To avoid this manual rework, a shared parameter will provide automation.

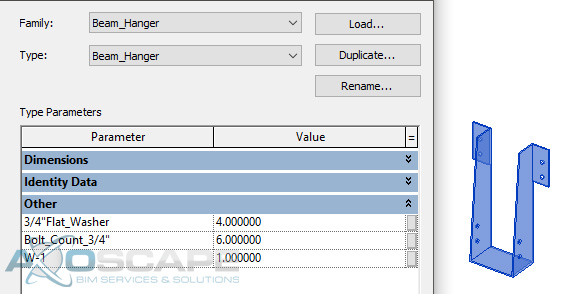

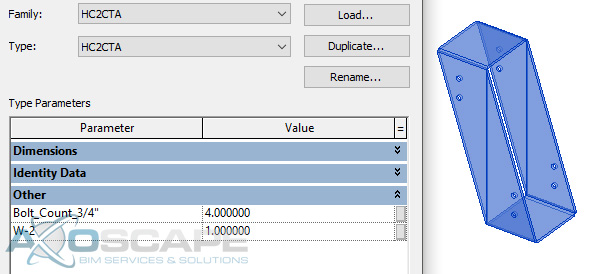

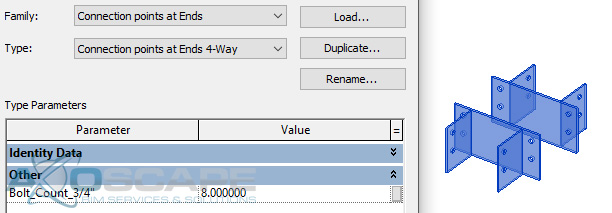

- Create family parameters for each connection in the Other category (Structural Stiffener category).

- Create shared parameters required for each family.

- Generate structural stiffener schedules for the connections.

Once you have all this information preloaded in the connection families, updates to scheduling are automated. Making it simple for the user to keep accurate counts on every component dynamically.